Quality Power Transmission and Material Handling Services

Quality Power Transmission and Material Handling Services

Quality Power Transmission and Material Handling Services

Quality Power Transmission and Material Handling Services

Quality Power Transmission and Material Handling Services

Quality Power Transmission and Material Handling Services

Industry Exploration Interactive Tools

Strengthen your Knowledge.

There is much to know about our products, capabilities, strengths and advantages, that’s why we’ve prepared this training as an initial introduction to the world of Martin, we hope it becomes a tool to strengthen your knowledge of our products. You can enroll to our available trainings by clicking on the product of your choice. We look forward to your feedback, and for any inquiries please contact us at learning@martinsprocket.com Enjoy your training!

Sign Up

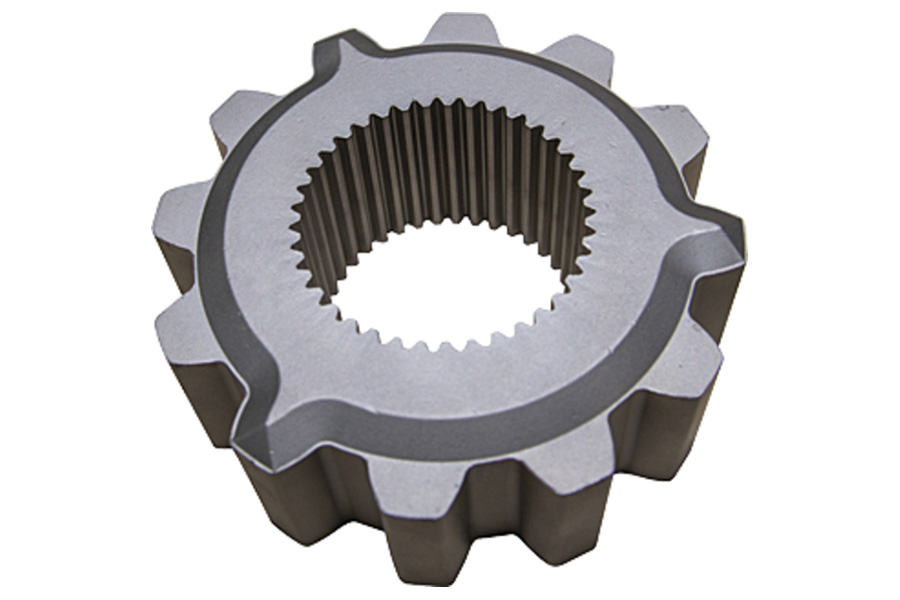

Our Line of Products

Industrial experts rely on Martin for three simple reasons: we deliver quality product, we offer the industry’s leading inventory of stock parts to meet any schedule, and we do whatever it takes to take care of our customers. From sprockets and power transmission components to hand tools, from bucket elevators to conveyor pulleys - we’ve got you covered.

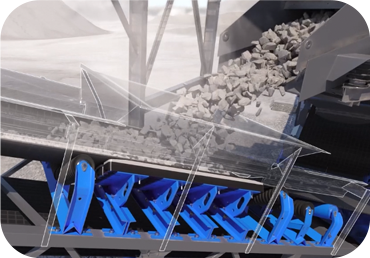

Mining

Mining is the extraction of valuable minerals or other geological materials from the earth. We have grouped 5 different types of material: iron ore, non-ferrous precious metals (gold, copper, silver, nickel, diamonds, zinc, etc.), coal, salt and sand, quarry and aggregates, potash and phosphate.

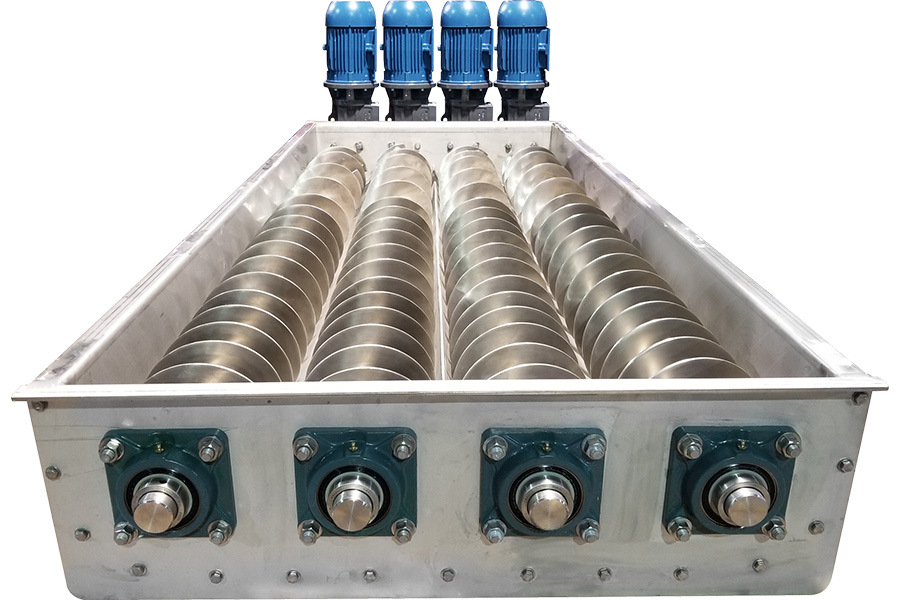

Learn MoreWastewater

Wastewater is any water affected by human use. It is a byproduct of domestic, industrial, commercial or agricultural activities. The main processes found in a typical wastewater plant include: screening process, aeration and settling tanks, grit chambers and sludge processing.

Learn MoreSalt

In the salt industry there are 4 main types of salt products. Rock salt mainly used for road deicing, brine salt used mainly for chemical industries, evaporated salt commonly used in the food processing industry, and solar salt used in the oil and gas industry, among others.

Learn MoreEthanol

Ethanol is a renewable, domestically produced alcohol fuel made from plant material, such as corn, sugar cane, or grasses

Learn MoreSugar

Sugar is a substance generally used to sweeten food and drinks, its various types are obtained from different sources. The main processes found in typical sugar cane and sugar beet plants are: receiving, juice purification, evaporation and crystallization, drying and packaging.

Learn MoreCement

Cement is the most utilized construction material in the world. Generally made by grinding calcined limestone and clay to a fine powder, which can be mixed with water and poured to set as a solid mass or used as an ingredient in making mortar or concrete. The main processes found in a typical cement plant are: conveying, screw feeders, silos, hoppers, kilns or dryers, scale belts, shaker hoppers, and bagging systems.

Learn MoreHelpful Info and Practical Tips

Helpful resources, product updates & industry news.