Martin manufactures drag conveyors available in several styles

Martin drag conveyors are available as round bottom, flat bottom, mill duty, and L and S path. Drag conveyors are well suited for ash handling, wood waste, grain and dust removal.

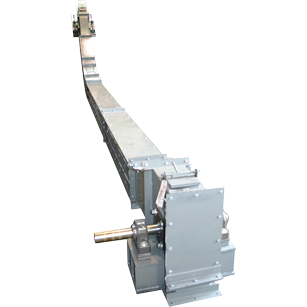

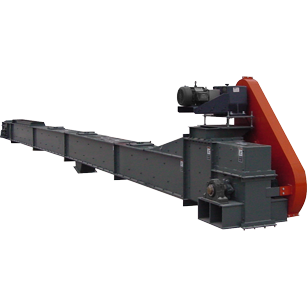

Flat Bottom Drag Conveyors

Ranging in capacities up to nearly 32,000 CFH these systems are constructed with heavy-duty formed channel sides, and a bolted bottom pan for quick and economical replacement.

Catalog | Literature | Safety & Installation | Online Training

Request Online Quote

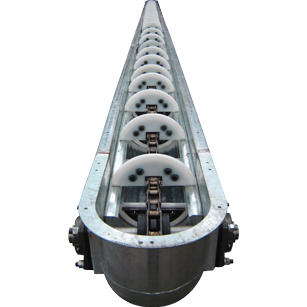

Round Bottom Drag Conveyors

Uniquely designed with an elevated head and tail section helps reduce noise, vibration and chordal action which results in a reduction in maintenance and operating cost.

Catalog | Literature | Safety & Installation | Online Training

Request Online Quote

L-Path Drag Conveyors

Allowing for a bend within the system allowing for a reduction in equipment. Under proper design these systems can discharge from a vertical position.

Catalog | Literature | Safety & Installation | Online Training

Request Online Quote

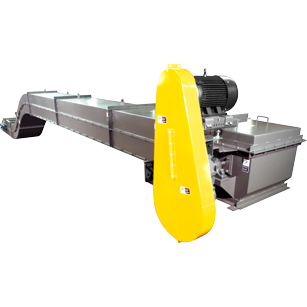

S-Path Drag Conveyors

This system includes two directional changes to eliminate the need for additional systems. It may also be successful in reducing expensive plant layout changes by bending the system around structural obstacles.

Catalog | Literature | Safety & Installation | Online Training

Request Online Quote

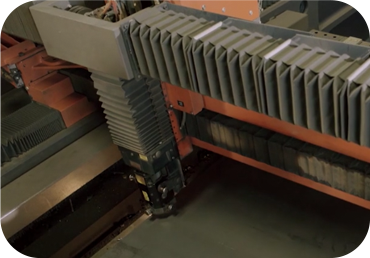

Mill Duty Drag Conveyors

Designed with drop forged chain, sprocket and flights make this system ideal for handling heavy and abrasive products.

Catalog | Literature | Safety & Installation | Online Training

Request Online Quote